EMS2005: For pristine accounting

EMS2005: for pristine accounting

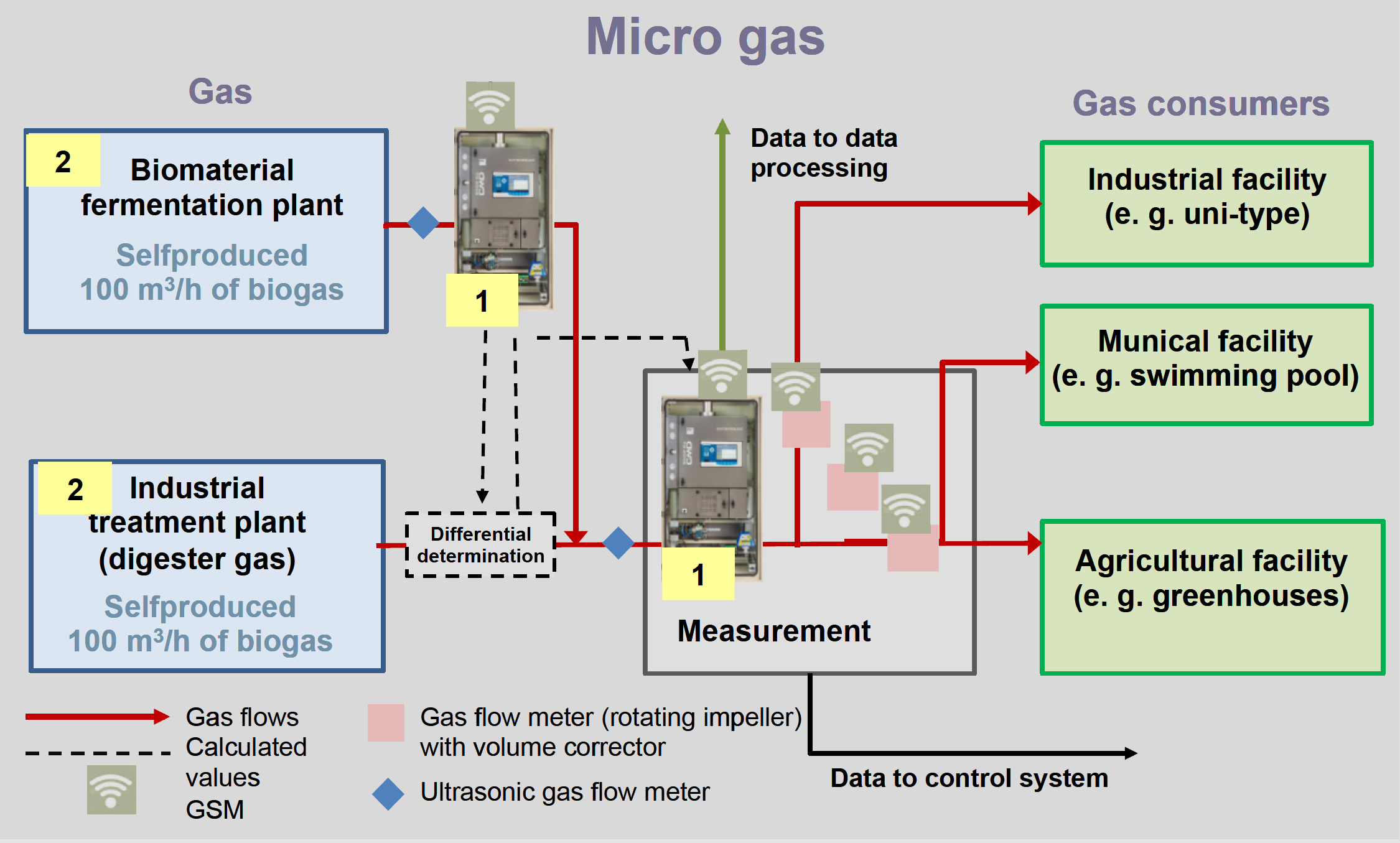

The EMS energy measurement system for autonomous micro gas networks with remote data readout and a reliable allocation method

Decentralized energy concepts are on the horizon

An important element of current, new energy concepts in many countries is the decentralization of energy production and supply. This trend is a move away from large centralized power plants with long power transmission distances and strong vulnerability to malfunctions towards decentralized, locally built integrated systems made up of energy producers and consumers. These systems, in turn, may be part of larger, but still decentralized, networks or – under especially favorable conditions – can exist fully autonomously as a network of local partners.

Micro gas network with a generic energy measurement concept

Alongside studies which are more long-term in duration, local networks already in operation all have one thing in common: energy producers like industrial facilities which accumulate organic waste and/or biogas plants, as well as energy consumers like industrial facilities, municipal facilities and agricultural companies, are all located within close proximity in a region. Such an arrangement is especially ideal for the installation of a micro gas network which, in addition to the transport of gas from the producer to the consumer, also provides data for the fiscal allocation of supplied and accepted energy quantities using an appropriate measurement concept. In view of the typical baseline of gas producers and consumers being located in close proximity to one another, this measurement concept is generic in nature and can be adapted to the respective conditions without great effort.

EMS2005 energy measurement system with remote data readout for fiscal allocation of energy supply

The overall system constructed by UNION Instruments for a micro gas network – comprised of gas measuring technology, measured value acquisition, measured value processing and remote data readout – includes the following modules:

- Gas flow meters in the lines of the gas suppliers (measurement principle: rotating impeller/ultrasound) and the consumers (measurement principle: rotating impeller) for determination of the respective gas quantities by calculating the difference.

- EMS energy measurement systems (CWD calorimeter with combustion value/volume corrector) for the continuous determination of the energy content of gases

- A centralized measurement and node point for the merging and preprocessing of the measured and calculated values and their forwarding to a control system

- Remote readout of all allocation-relevant data via GSM to a data processing center featuring data compatibility with the established invoicing methods

The system enables the continuous determination of the supplied/accepted energy quantities, thereby creating the requirement for transparent, consumption-based energy allocation through the use of established allocation methods.

INCA gas analyzer for process monitoring

An important part of the system is the monitoring and optimization of biogas production with regard to efficiency and gas quality. This is achieved by a gas analysis which specifically monitors fermentation and the subsequent desulfurization through measurement of the respective gas compositions. One special challenge here is monitoring of the high proportion of hydrogen in the gas resulting from a hydrolysis step. UNION Instruments has the solution to this challenging application in its INCA gas analyzer. The high hydrogen concentration also affects the combustion value of the gas recorded by the calorimeter in the EMS. The other measured components monitored by INCA are CO2, CH4, and H2S. The determination of H2S in this case is another difficult application of the gas analysis.

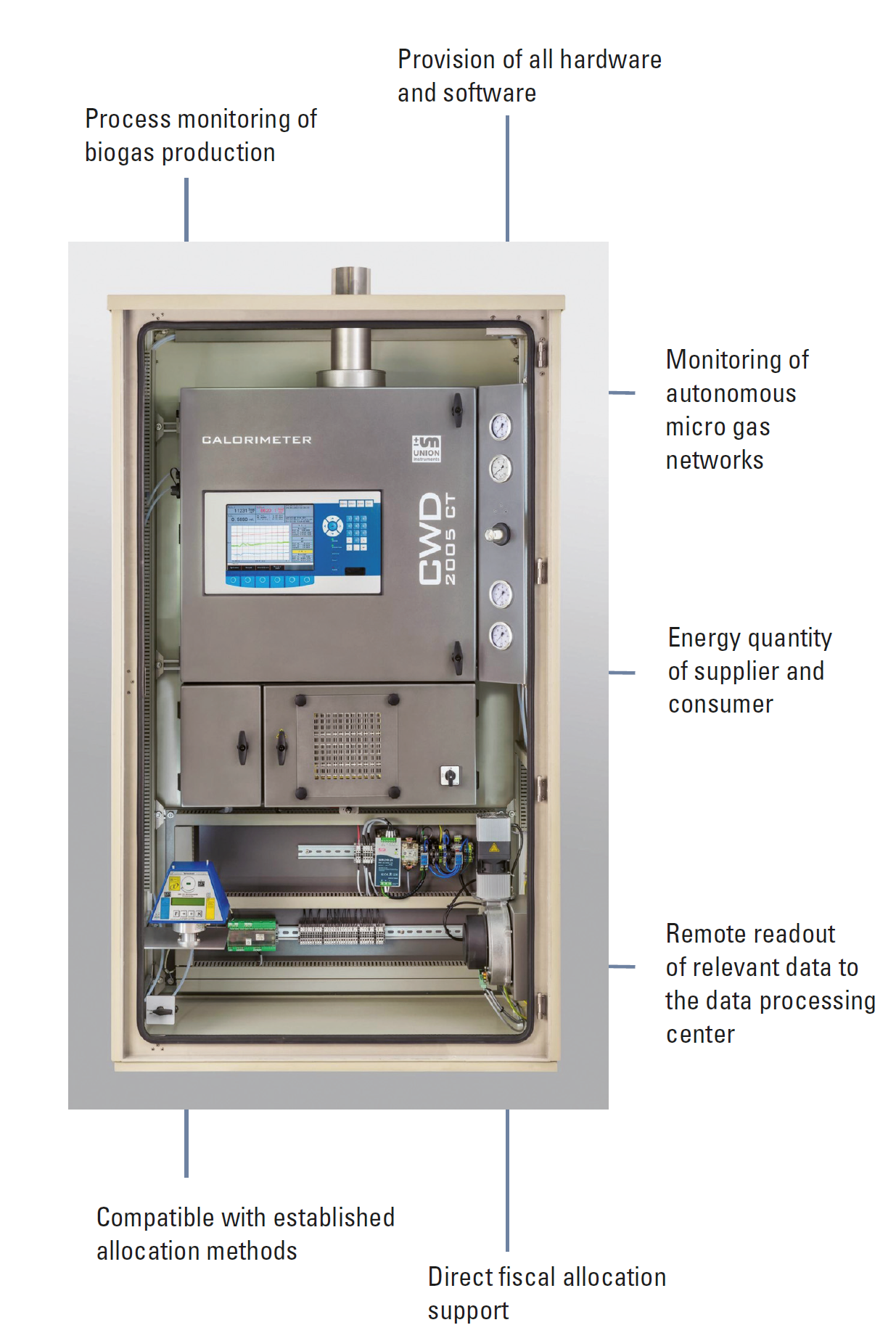

EMS2005 (energy measurement system)

EMS2005 from UNION Instruments is a measurement system for the determination of – in the form of combustible gases – the transported/supplied energy quantities. The EMS2005 is comprised of modules for determining the volume flow, pressure, temperature, moisture and energy content of the gas and an energy corrector. As the resulting measured value, the recorded (supplied) energy quantity is output over a defined period of time. The EMS2005 is used as the basis of allocation for the fiscally relevant transfer of biogas, biomethane and natural gas between different gas producers and/or gas network operators, as well as for the supply of end users like municipal utilities and industrial operations. The main component of the EMS system is the CWD2005 calorimeter. The system can also be used to determine the energy in moist raw biogas by being outfitted with sensors for moisture measurement and heated gas lines and by being installed in a heated cabinet. Naturally, this measure can be omitted with the device version used for the measurement of dry gas.